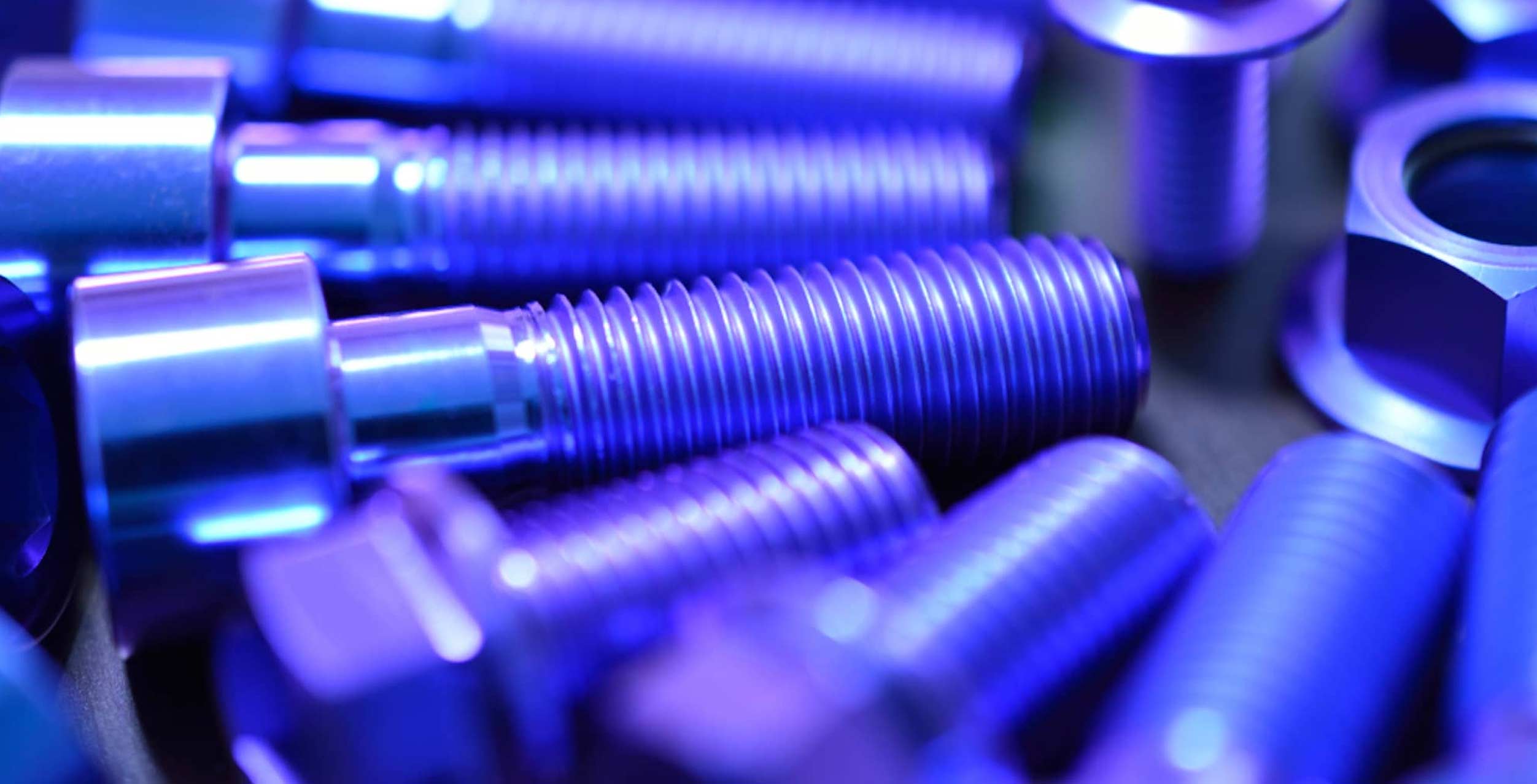

Color Anodizing

Color anodizing is a process that involves adding color to the anodized oxide layer on the surface of a metal, typically aluminum. This process allows for the creation of a wide range of colors and shades, from bright and bold hues to subtle and muted tones.

Benefits of Color Anodizing:

Aesthetic Appeal

Color anodizing provides an opportunity to add color and style to a wide range of products, including automotive parts, consumer electronics, and architectural elements.

Durability

The anodized oxide layer is hard and scratch-resistant, providing a durable and long-lasting finish that resists fading, chipping, and peeling.

Corrosion Resistance

The anodized oxide layer provides an added layer of protection against corrosion, making the metal more resistant to damage from moisture, salt, and other corrosive substances.

Electrical Insulation

Color anodizing can create an electrically insulating layer on the surface of the metal, making it useful for electronic and electrical applications.